22mm_ematch_test_edit from concretedog on Vimeo.

So I've been plugging away on a few projects slowly in the background over the last couple of months one of which is developing a collection of stackable 22mm diameter PCB which are designed to fit inside a common small estes rocket body tube diameter but also could be used for all kinds of rocket or none rocket related projects.

I'll come back to those but breifly wanted to show the video above which is a prototype of an ematch ignition system that I've made using my 22mm boards. At the moment the circuit awaits a defined delay time and then fires a mosfet to send the current to the ematch ignitor. These type of systems are used sometimes in high power rocketry to ignite a small black powder or pyrodex charge to separate 2 sections of a rocket to deploy a parachute for recovery. Sometimes instead of a timer the ignition circuit is linked to an altimeter to deploy the charge and resulting chute at a specific altitude on the way back down.

So back to the 22mm project.. I realised I was at risk of forgetting what little I know about KiCad (my preferred opensource electronics PCB design package) and wanted a project and have though for a while a collection of useful small boards would be worth having. So I've designed two boards so far and had them made by OSHpark which has been a fabulous experience... you don't even have to battle to get your gerber exports sorted for OSHpark as they will work directly from a KiCad PCB file... just upload... check the preview render of the board layers in your browser and if ok... hit order!

So far I have a board for SOT89 power regulators and a board with an Attiny85 and some power indicators and an LED! The next board will be basically a prototyping board (think veroboard in the 22mm form factor) and I have a few ideas beyond that. I am determined to (after the prototyping board is done) to get all the files on github so anyone can order some if they think they might be useful. They stack and have holes for M2 threaded bar which is connected to ground to minimise power wiring.

Some pics of the boards

Sunday 31 December 2017

Saturday 30 December 2017

Turning Graphite Nozzles

I've been reading a lot on hybrid rocket engines over the Xmas break and although I am nowhere near ready to actually start building a hybrid engine (apart from that micro hybrid I started YEARS ago maybe!) I wanted to do something practical and decided to turn out a graphite nozzle on the lathe. Mainly to get a feel for how graphite machines ... which the answer is.. astonishingly easily! It cuts very well with little regard for speeds and feeds and responded well to standard HSS tooling.

Although I am working through the maths in the hybrid book I am looking at, I'm not actually at the point where I have a design. So this nozzle is just made with similar dimensions to a Laval nozzle drawing in the book with a 30 degree angle for the nozzle side and a 45 degree angle for the combustion side. I'm pretty pleased with it as a test piece and its certainly given me a feel as to what is possible in graphite.

Above is the 45 degree side that would face the combustion chamber.

The 30 degree nozzle side and the arbitrary sized throat.

Tuesday 5 December 2017

INSPACE TWO 30/11/2017

So yes, last week INSPACE TWO happened, the second event I've organised as part of the INSPACE program and run as a North Wales Tech event with the support and venue of API pontio. This time the theme was earth observation using the open and available Copernicus data returned by the fleet of Sentinel satellites as well as some earth based data collection.

In truth I didn't personally have to do much on the night! I stuck together a quick introductory set of slides about the rationale behind picking this topic for the event and a brief overview of the Copernicus program and the Sentinel fleet. I then handed over to the fantastic Dr Jamie Williams and Anthony and Sebastian from the Aberystwyth based company Environment Systems. They very kindly then took the around 30 delegates through how to use the enterprise and free versions of their API allowing the participants to download data of various types (imaging/radar etc) and import it into the opensource QGIS environment. Massive thanks to the EnvSys team who were fantastic and worked the room well after some excellent presentations and got everyone going with their systems.

Huge thanks also go out to S2 recruitment who again kindly sponsored our pizzas which fuelled the workshop well and by the end of the 3 hours everyone had learnt a lot and managed to download and begin to play with some data... from space... :)

I spent the night floating around and chatting to people and heard a good spread of existing and emerging ideas for use cases for earth observation data both in commercial terms but also definitely spoke to some participants who had found new ideas they could utilise in their academic research.

So finally.. one more thank you to the Envsys team, to API pontio for the venue and equipment, to S2 again and a huge thank you to Carwyn from North Wales tech who puts in a huge amount of work all the time to make the NWT events program as rich and as varied as it is.

Stay tuned for details of INSPACE THREE!

Friday 1 December 2017

My talk at the amazing OSCW17, Open Source Cubesat Workshop.

Its been a busy couple of weeks, last week, most excellently I got the opportunity to go out to the ESA (european space agency) centre of operations in Darmstadt, Germany to be at and speak at the inaugral Open Cubesat Workshop. My talk starts around 24 minutes in to this video below..

Put together by the Libre Space Foundation, the Librecube initiative and ESA/ESOC Cybernetics Team this was a fabulous 2 day event featuring a mass of speakers and delegates from all around the globe coming together to share their work around opensource space and Cubesat themes.

Featuring speakers, demo areas, an ESOC facility tour, breakout workshops, and much much more I think this conference was a triumph. It was so impressive to meet people who had traveled from places such as a team from Japan, a crew from an Argentinian robotics/maker club, the brilliant Greek Librespace lot, Poland, France, Russia and even Wales.. :) I made plenty of new friends and really look forward to supporting and helping the team for OSCW18.

If you are interested the whole of the conference talks were captured and are on this youtube playlist

https://www.youtube.com/watch?v=KnoYzqAw_vM

I chucked together a storify of all the tweets that went out on the conference hashtag #oscw17 which is here...

Monday 13 November 2017

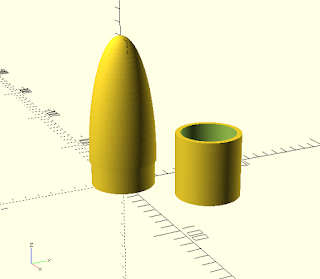

Opensource Rocket nosecone, transitions and couplers... OpenSCAD sketches.

Just in case it's useful I decided I'd chuck a few bits of openSCAD code I use to generate 3d models of transitions and nosecones and couplers for rockets onto github. I am no amazing coder but it's nice to opensource what little I can! Its pretty well commented so you just stick in the dimensions you need and render!

IT'S HERE!

Saturday 4 November 2017

Rocket Rail buttons... and shaving weight!

(Obligatory lathe shot above!)

In high power rocketry often a rail is used to launch the rocket rather than a simple rod as the aluminium tee slotted extrusion ( the same types that many 3d printer or hobbiest cnc router frames are made from) is more stable and rigid. This means that instead of a launch tube/lug being mounted to the rocket airframe a pair of rail buttons that slide into the slotted extrusion are added instead.

I struggled when I was building Panta Rhei for my level one certification to find out which rail buttons I needed or indeed the dimensions of the ones I needed as I hadn't ever been to a high power event. However I eventually discovered there are 2 types of rails commonly used, the 2020 rail with a 6mm slot or the 3030 rail with an 8mm slot.. Eventually a very kind UKRA member (driven mad by my constant questions) took pity on me and sent me a set of rail buttons that would fit a rail that would be used at the launch event I was aiming for.

They worked brilliantly and I've been doing a few experiments to make further rail buttons to try and shave the weight and also to be able to use a metric fit as the commercial ones use a 3/16 machine screw to fit them. People who know will know have a bit of a thing about using SI units... but also I think that the 3/16 screws with quite a course pitch thread when usually being fitted into 2 -4mm wall thickness they don't really offer an optimal thread type/contact area. So above is a picture of the commercial ones aimed to be used in a 6mm slotted 2020 rail.

Above is the first set I turned up, here I used Delrin which has a higher Young's modulus than nylon (which I believe the commercial ones are) and is very free to machine and also has a self lubricating quality as you can see about fitted with M3 12mm bolts (with a large head) offers almost a 2 gram saving over the originals.

So I also had a go at turning some out of Nylon and again they represent a weight saving over the originals even though the actual Nylon piece is slightly heavier than the original the M3 bolt weight saving makes a saving overall.

So I think the future is Delrin.. stronger and lighter!

Sunday 29 October 2017

Derby Mini Maker Faire 2017 Photodump!

So travelled down to Derby yesterday to see the Mini Maker Faire... mainly becasue it is an ace proper maker faire and also the venue is closing for a couple of years for a large refurbishment project so its the last one for a while! Had a fabulous time and saw loads of amazing people and things!

So many cool robots in the place!

Me and the fabulous KonichiwaKitty... :)

Spencer... Mr RC2014, maker of extraordinary retro computing kits!

Fascinating bit of machining this... a WWII bomb made by Qualcast ... yep thats right Qualcast the lawnmower company, this is one of the many objects being digitised into an archive of models at Derby Silk Mill museum.

Singing TESLA COILS.... So utterly brilliant... working out how we can get aload of these into a space in NWales!

Derby Silk Mill makerspace has this MASSIVE cnc... it must be able to take 3 8x4 sheets... tis a beautiful monster!

Bristol Hackspace had this brilliant manual machine for drawing great images!

Kids making supercool LED ghost badges!

Pimoroni injection moulding mould for pirate coasters!

Not sure anyone could spot Steve all day...

My kids loved Jarkmans mahoosive controllable inflatable tentacle!

Coretec robotics battles!

Ben from Boldport exhausted at the end!

The astronauts caravan... wow... a weird spinny experience!

Sunday 15 October 2017

15 minute make! Small router table

Hole cutting drills.. I always tread carefully with these as they seem to want to fling the drill about as they engage!

Couldn't be simpler way to mount the table... and yes ... my shed needs tidying!

Friday 13 October 2017

DoES Liverpool Rocket Design Workshop

Heres a few shots from last night!

Not a bad turnout with a couple of people also not in this shot!

Didn't take many shots of the different spaces but here's one!

Some very nice 3d printers including a sweet Ultimaker extended (good for BIG nosecones!)

Do we get the pun?! A cheesey rocket pizza.... Top work and great pizza was consumed!

ESTEC European Space Agency open day

So, went over to Noordwijk in the Netherlands last weekend to attend the Open ESTEC day with thousands of other people! ESTEC is the technical heart of ESA and they open a massive amount of it and a load of the staff volunteer to come back in to talk about the work that they do. It was a fabulous day and met some wonderful people. I took far to many photographs to upload them all so for now I though I'd chuck some of the tweets I did in the storify below. It was great to see all the science and technology but additionally brilliant to meet up with a few people again or for the first time! Most notable was to meet Montasser who works at Innovative Solutions In Space who I have talked to for 4 years and even been on a Hackaday Prize team with but had never met irl. I also got to see the DARE rocketry team (blog from when I visited them earlier this year here) and also got to see Jasper from the Delfispace program who does a lot of work on Pocketqubes. A fabulous event.. if you get the chance to go... GO!

Subscribe to:

Posts (Atom)