Had a great day at the mighty

Liverpool Makefest It was great to catch up with a lot of people and see some amazing projects. I'd tweeted about wearing my

SatNOGS tee shirt and was really pleased that lots of people wanted to catch me for a quick chat about that project, Indeed the very next day

DoEs Liverpool got a simple SatNOGS station up and running. Anyway... here is a quick round of photos with some quick notes in no particular order!

So the first people me and my daughter chatted with were the mighty

#GirlsWithDrills crew. I've been a fan of their vital work to make maker culture inclusive, equal and equitable. Bought my daughter a tee shirt and after a fab chat went in.

Quantum technology club has an amazing sign that did music and light sequences and was very cool. Brilliant to see this lot were talking about radios, had a CW (morse code) practice activity set up and had an SDR setup etc. They were really keen on the SatNOGS project and also chuffed to be introduced to

HackSpace magazine and started downloading digital editions whilst we were chatting!

Coretec robotics! Stallwarts of maker events throughout the lands, great to catch up with them and Seren enjoyed working through the make a flying spinny disc activity (build a simple driver circuit, connect it to a Pi, write/code a simple python script to spin up a motor to launch a flying spinning disc). As usual Coretec had a plethora of amazing robot builds including a nice balancing one seen below.

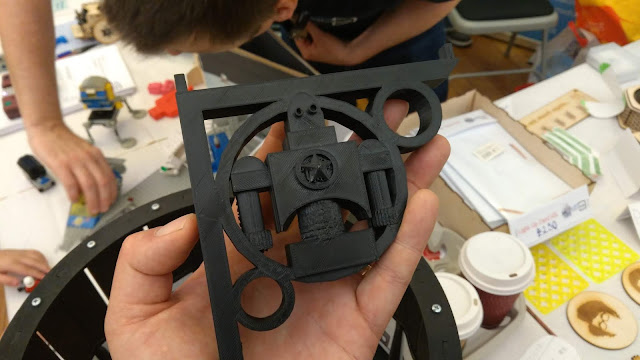

This 3d printed shelf bracket is one of the many amazing things on the

little sandbox stall. This project is typical of little sandbox and shows how brilliant they are... They get their young people to design and build things like this that become part of the spaces they use, it helps create a sense of ownership for the young people over the project as well as teaching them some skills. Fab. They are also actively pursuing SatNOGS as a project and Rocketry... LEGENDS!

Around 11 am and the bottom floor starting to fill up.

Fabulous racoing game... the brio track has been fitted with neo pixels and the controllers (to make your pixel travel round the track) were those hand crank generating torch things. It was a fantastically playable game... I loved the details such as you needed to crank harder and generate more power to get up the hill or you would roll back and you would then accelerate on the downhill... Brilliant.

THE MIGHTY LES P.

York Hackspace as ever had some amazing stuff on display including this gorgeous Altair 8000 project!

Above and below... 2 different versions of the classic snake game... It really entertained me that at Makefest you could play 1 dimensional, 2 dimensional or 3 dimensional snake in different parts of the show!

The fabulous

Lorraine with her Cubert project right by the front door! A busy day for her with a fabulous project.

And finally Mark Mellors and his

Hacky Racer, I got to have a sneaky little go and I have to say a Hacky Racer project is definitely on the list of future projects.

So there we go.. a great day out... If you haven't been to Liverpool Makefest you really should... it's fab!