Machined out these small aluminium charge wells for deployment charges for rocketry. I have used small copper plumbers endcaps before now but needed slightly more capacity and I wanted to try and make them in a way that the E-match wires would sit flush through a small slot, making them easier to seal. As I use Pyrodex rather than BP it's important that the seal is good to contain the Pyrodex correctly.

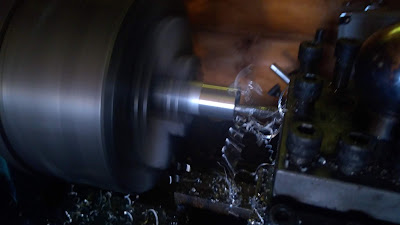

Machining them was pretty easy, I turned some stock down to 20mm diameter and centre drilled a 5mm hole for an M5 fixing (I potentially could have used smaller but I needed 5mm to give clearance for the home ground HSS boring bar). Then I bored them out to leave a 3mm wall thickness and parted them off on the lathe.

Having parted them off I decided that they were a little too long for my needs and I milled a couple of mm off each of them as there is no use carrying that weight if you don't need it! I then used a small endmill to mill the small slot.

It's nice to be able to try these ideas and I love machining parts for rockets... I mean I could just buy everything but where the fun in that! :)

No comments:

Post a Comment